Maximize

Maximize

Maximize

Maximize

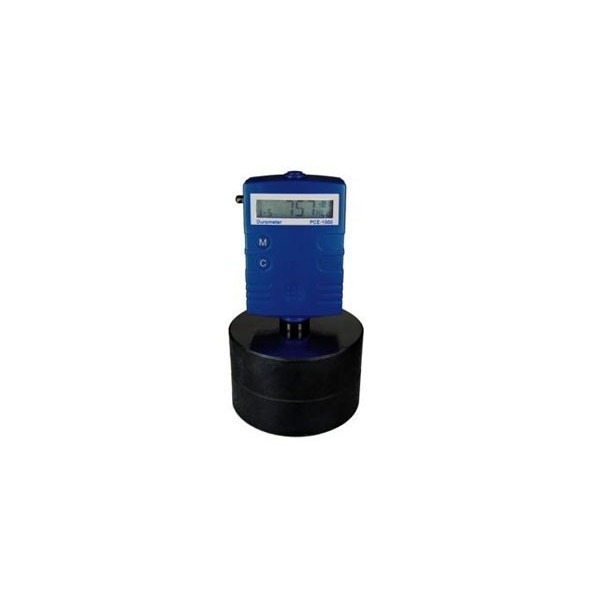

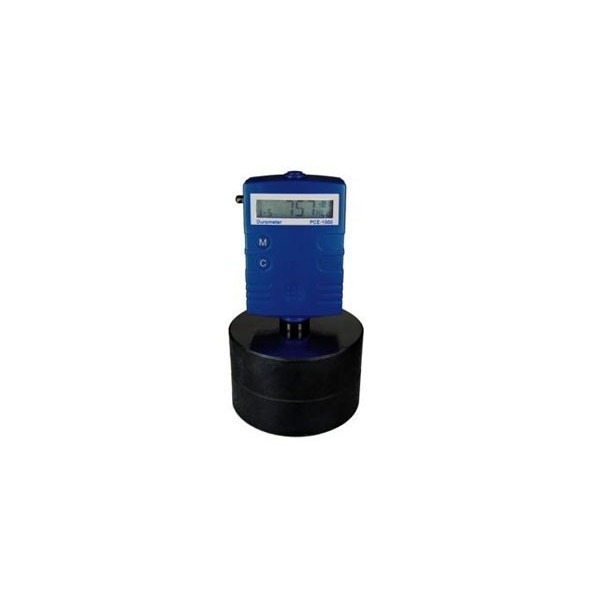

Hardness tester Vickers 1000 is ideal for testing the surface hardness of metallic surfaces quickly. In metallurgy, its very important to know the hardness of the materials being used and this device allows for the materials to be tested in the factory. The hardness tester brings together the parameters of Rockwell B & C, Vickers HV, Brinell HB, Shore HS and Leeb HL. Thanks to its portability, this hardness meter is very useful in production, quality control and technical service. Its compact design and rechargeable battery makes this a very easy device to use.

The Leeb measurement method was used for the first time in 1978. It is defined as the rebound velocity of the hammer divided by the impact velocity times 1000. The higher the value, the higher the hardness of the material being measured. For a specific group of materials, such as steel and aluminium, the Leeb hardness test establishes a direct relation to the materials hardness conditions.

This device includes the conversion curves for HL hardness and for other standard static hardnesses such as HB, HV and HRC with the possibility to convert Leeb into other values and display these. Therefore, this is a device for professionals to be used for shipping and receiving, production or research and development.

Features:- pocket-sized device that requires minimal space.

- measures the typical parameters.

- integrated instrument without cables.

- wide measurement range.

- highly accurate.

- can measure from any position.

- rechargeable battery and charger included.

- wide variety of optional adaptors.

Technical specifications:

|

Measurement ranges |

|||||

|

|

HRC |

HRB |

HB |

HV |

HSD |

|

Steel/ iron |

20 ... 67,9 |

59,6 ... 99,5 |

80 ... 647 |

80 ... 940 |

32,5 ... 99,5 |

|

Tools |

20,5 ... 67,1 |

|

|

80 ... 898 |

|

|

Stainless steel |

19,6 ... 62,4 |

46,5 ... 101,7 |

85 ... 655 |

85 ... 802 |

|

|

GC. iron |

|

|

93 ... 334 |

|

|

|

NC. iron |

|

|

131 ... 387 |

|

|

|

Cast aluminium |

|

|

30 ... 159 |

|

|

|

Brass |

|

13,5 ... 95,3 |

40 ... 173 |

|

|

|

Bronze |

|

|

60 ... 290 |

|

|

|

Copper |

|

|

45 ... 315 |

|

|

|

Scales of hardness |

HL, HRC, HRB, HB, HV, HSD |

||||

|

Types of materials (adjustable) |

STEEL CWT. STEEL STAIN. STEEL GC. IRON NC. IRON C. ALUMIN BRASS BRONZE COPPER |

||||

|

Accuracy |

± 6 HL para HL = 800 (0,8%) |

||||

|

Instrument of percussion |

type D (integrated) |

||||

|

Minimum hardness |

940 HV |

||||

|

Radius of the moving component (convexed / concaved) |

R min = 30mm (with 10mm component) |

||||

|

Minimum weight of the moving component |

5kg without base 2 to 5kg with base 50g to 2 kg with base and accompanying board |

||||

|

Minimum depth of the moving component |

3mm with accompanying board |

||||

|

Minimum penetration |

0,8 mm |

||||

|

Power |

9V DC rechargeable |

||||

|

Operating time |

12 h |

||||

|

Maximum temperature of the moving component |

+ 120 °C |

||||

|

Operating temperature |

0 ... + 50 °C |

||||

Follow us